Located in Iceland, it is the first system in the world on an industrial scale to remove carbon dioxide from the atmosphere and store it underground; measure aims to combat global warming

To try to help combat global warming, the Swiss company Climework developed the first system in the world, on an industrial scale, which aims to reverse the rise in greenhouse gas emissions. The solution consists of a plant built in Hellisheiði (Iceland), named after Orca, which captures carbon dioxide (CO₂) from the atmosphere and stores it in the ground.

According to the company, the plant’s facilities have been operating since September 2021. In the Nordic country, Orca has the capacity to remove 4,000 tons of CO₂ in the air, what equivalent to the gas emissions of 900 gasoline-powered cars.

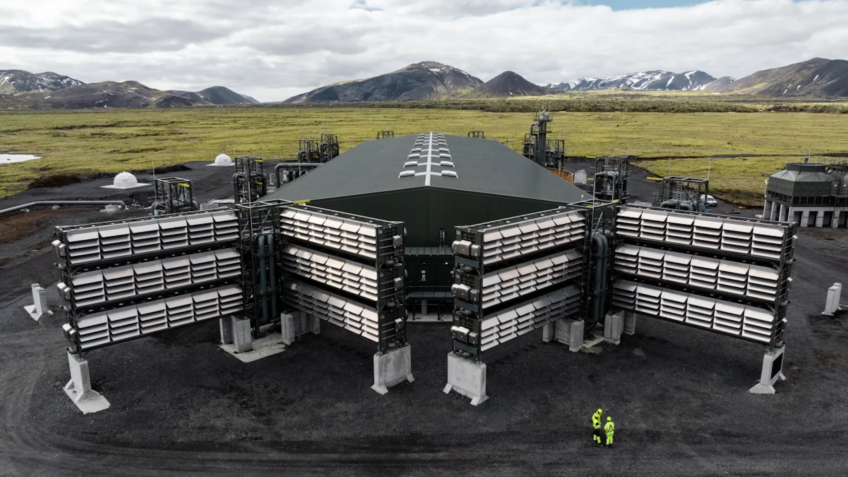

With even greater purposes, on May 8, 2024, the Swiss company opened a 2nd facility, also in Iceland, close to the capital Reykjavik, named Mammoth, 10 times larger than its predecessor. The initiative increases the capture capacity to 36,000 tons of CO₂ per year. The goal is to eliminate millions of tons from the atmosphere by 2030.

According to data from the IEA (International Energy Agency), global carbon dioxide emissions reached 37.4 gigatons (37 billion tons) in 2023. Here is the full report (PDF – 1 MB, in English).

CO₂ capture

According to Pedro Luiz Gomes Martins, researcher in the field of geosciences at UnB (University of Brasília), there are various technologies to capture CO₂ from the atmosphere.

“Key technologies include post-combustion capture [depois da queima de combustíveis fósseis], pre-combustion capture [antes da queima] and direct capture from the atmosphere. After capture, the CO₂ is purified and compressed to facilitate transport.”declared to the Poder360.

Already Climework direct capture in the air is used and then transported to the storage location. The gas is then injected into suitable geological formations underground, which in the case of the facilities in Iceland, are in basalt (porous sedimentary rocks) and is then stored for 10,000 years.

“CO₂ is injected at a depth where it is under high pressure and temperature, where it reacts with minerals in the geological formation and transforms into stable carbonates over time”explained Martins.

In Iceland, another company stores gas underground, CarbFix. Furthermore, this entire process requires a monitoring phase.

“Finally, monitoring and safety must be carried out during and after the injection, to ensure that the CO₂ remains confined and does not leak back into the atmosphere. This involves monitoring the pressure, temperature and integrity of geological formations, as well as detecting potential leaks,” informed the researcher.

Installations in Iceland

Iceland was chosen mainly for its volcanic activity and for providing clean geothermal energy without greenhouse gas emissions. Furthermore, volcanic activity means that the country’s subsoils are mostly composed of basalts, which are the perfect container for CO₂ from the atmosphere.

For Martins, the project in Iceland may be the first on an industrial scale of its kind, but research like this has been under development for some time in different parts of the world. “There are other places in the world with favorable geological conditions for the implementation of carbon capture and storage (CCS) plants, especially where there is an abundance of basalt formations and geothermal resources”.

According to him, Norway, Japan, the United States, Australia and Canada also have potential for this type of installation. “These are just a few examples. Selecting suitable sites for CCS projects requires a detailed analysis of geological conditions, resource availability, and environmental and regulatory considerations.”these.

Commercially viable project

The representative of CarbFixEdda Aradóttir, said to BBC that the company’s objective is for large CO₂-emitting industries in the world to hire the company’s services to deposit their emissions in Iceland.

For Martins, the ability to capture and store CO₂ on a large scale is technically proven. “However, there are still technical challenges to be overcome, such as reducing capture costs, selecting suitable storage locations and ensuring the safety and stability of geological formations.”

Regarding the economic issue, the cost of capturing, transporting and storing CO₂ is still relatively high compared to other forms of reducing emissions. The total cost can vary significantly depending on specific project conditions and local conditions, such as infrastructure availability, skilled labor, environmental regulations and available financing.

For the researcher, it is possible to reduce costs with time and accumulated experience. “Additionally, government policies such as tax incentives and carbon prices can make CCS more economically viable”he stated.

Possibilities for Brazil

Brazil has vast areas made up of basalt rocks, especially in the South region – known as the Paraná Basin. These locations may have potential for CO₂ mineralization, according to a published study in the magazine Nature. Here is the full text (PDF – 4 MB, in English).

AND It is important, however, to carry out detailed studies to assess the specific potential of each area in Brazil for implementing basalt-based carbon capture and storage projects.

With appropriate investments in research and development, Brazil could explore its potential for CO₂ mineralization in basalts as part of its efforts to mitigate climate change and reduce greenhouse gas emissions.

Martins ends by informing that currently some research projects are being developed at federal universities, with the main objective of promoting the mineralization of CO₂ in the basaltic rocks existing in Brazil.

This report was produced by journalism intern Nathallie Lopes under the supervision of assistant editor Ighor Nóbrega.

Source: https://www.poder360.com.br/internacional/entenda-como-funciona-a-usina-que-captura-co%E2%82%82-e-transforma-em-rocha/